RC55

high hardness as 55 HRC exploding common knowledge about die-machining achieves outstanding machinability similar to the traditional machining before thermal processing.

| Features of RC55 |

|

| Applications | Position of RC55 | |

|

|

| Machinability | |

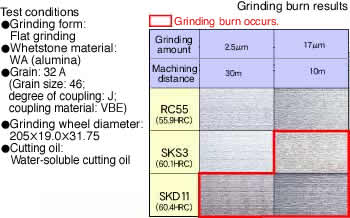

| End mill The RC55 has much better machinability for high hardness than the SKS3.  |

End mill(High speed machining) The RC55 has better ma 8chinability than the annealed SKD11.  |

| Roughing-end mill The RC55 is also applicable to rough machining with roughing-end mills.  |

Front milling machine Appropriate machining conditions allow cost reduction.  |

| Drill The number of drilled holes greatly differs with the machining conditions. It is important to properly select the conditions.  |

Tapping The RC55 also allows tapping, which is hardly done at high hardness.  |

| Machinability | Build-up welding characteristics | |

The RC55 has

a remarkably superior machinability to the SKS3. |

The RC55 allows

build-up welding in the same welding conditions as the flame- hardened

steel.  |

|

| Flame hardening characteristics | Surface treatment characteristics | |

The RC55 features

the flame hardening characteristics equivalent or superior to the

flame-hardened steel. |

The RC55 is

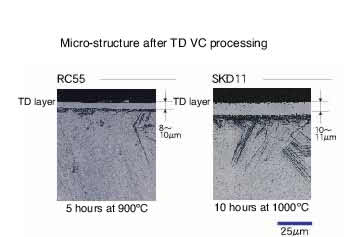

applicable to TD processing in the same conditions as the SKS3. Micro-structure after TD VC processing  |

|

| Tenacity | Surface treatment characteristics | |

The RC55 has

good tenacity and can reduce initial chipping of metallic molds. |

The RC55 has

equivalent wear-resistance to the SKS3 and flame-hardened steel. |

|