Our Business

4 strengths of JMS Engineering

Incorporating the knowledge and experience cultivated over many years in the special steel trades and mold manufacturing industry which is one of the core process of manufacturing, we originally developed and provide our “Total Solution” that is highly value added injection molding from material to design, system and analysis.

Beyond the boundaries of trading company, JMS has another face as the professional manufacturer of titanium and are heading to evolve continuously for The “Engineering Group”

Special steels

Utilizing the experience of steel trade for over 40 years, we have built a global network to meet the variety of needs in a wide range of fields from general purpose steel to super alloys and nonferrous metals. In the field of special steel, we can make optimum proposals for various requirements by making full use of Japanese manufacturers and networks with abundant overseas manufacturers.

What kind of metal is tungsten carbide? We will introduce its features, manufacturing process and application examples.

Titanium Material

As a professional manufacture of Titanium round bar and wire, we have two factories in JAPAN and CHINA. We produce and supply the material which meets various demands from our customers such as low cost, short delivery, small lot requirement and so on.

Titanium has characteristics such as lightweight(Specific Gravity: 4.51), high tensile strength and titanium alloy has the highest tensile strength comparing other practical metals that due to its characteristics, various usages can be expected.

We JMS make a proposal according to each customer’s demand by using our own drawing technology.

Mold Solutions

Our company is not only Design & Sales of molds but also utilizes various analysys of theoretical solution methods to foresee problems to find solutions and lead to design changes and parts selection, We provide the total solutions which does not remain any risk.

We propose "Monodzukuri reform" which incorporates the process of "foreseeing, discovering and realizing" in order to overcome the price reduction as well as differentiation from other companies

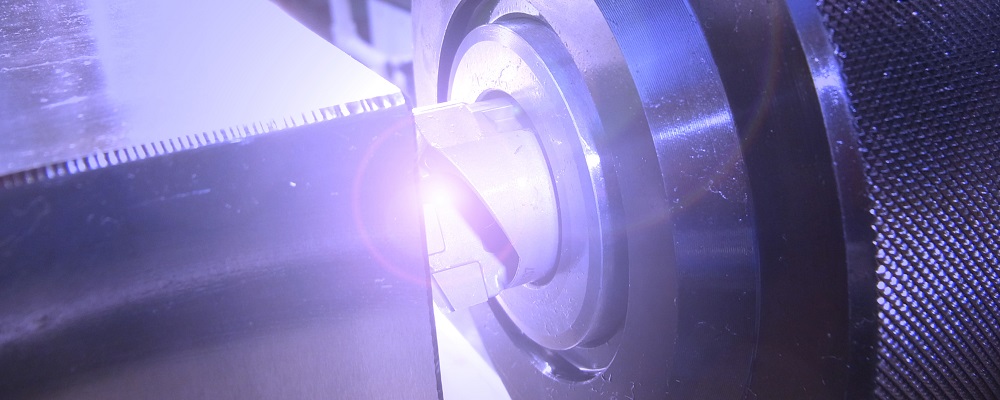

Machines

Tap Remover is a portable EDM enables you to remove broken taps, drills, screws without damaging the Screw thread inside,

Light weight in total 10kgs, can be adapted to nonvertical workpiece,

For big workpiece that can't be moved easily, You can bring Tap Remover to the workpiece.

Tap Remover is a great insurance for case of emergency.